The magnetic allure of gin, a versatile spirit celebrated for its rich array of flavors and characters, has a deep-seated connection with its intricate distillation process. The tantalizing dance of grains and botanicals, censorship by fermentation and distillation, and the anxious wait till bottling, interweaves a compelling story about this beloved spirit. Starting from roots buried in history to evolution guided by technology and economy, gin distillation emerges as a testimony to human creativity and the relentless pursuit of refined taste. As we traverse through the lanes of its diverse kinds, such as London dry, Old Tom, contemporary gins, and others, we discover that each distillation process echo unique melodies of flavor and character, making gin a symphony of spirits. Moreover, as eco-conscious practices reach the forefront, distilleries worldwide are reevaluating their operations to envelop sustainability at their core, subtly changing the direction of this age-old narrative.

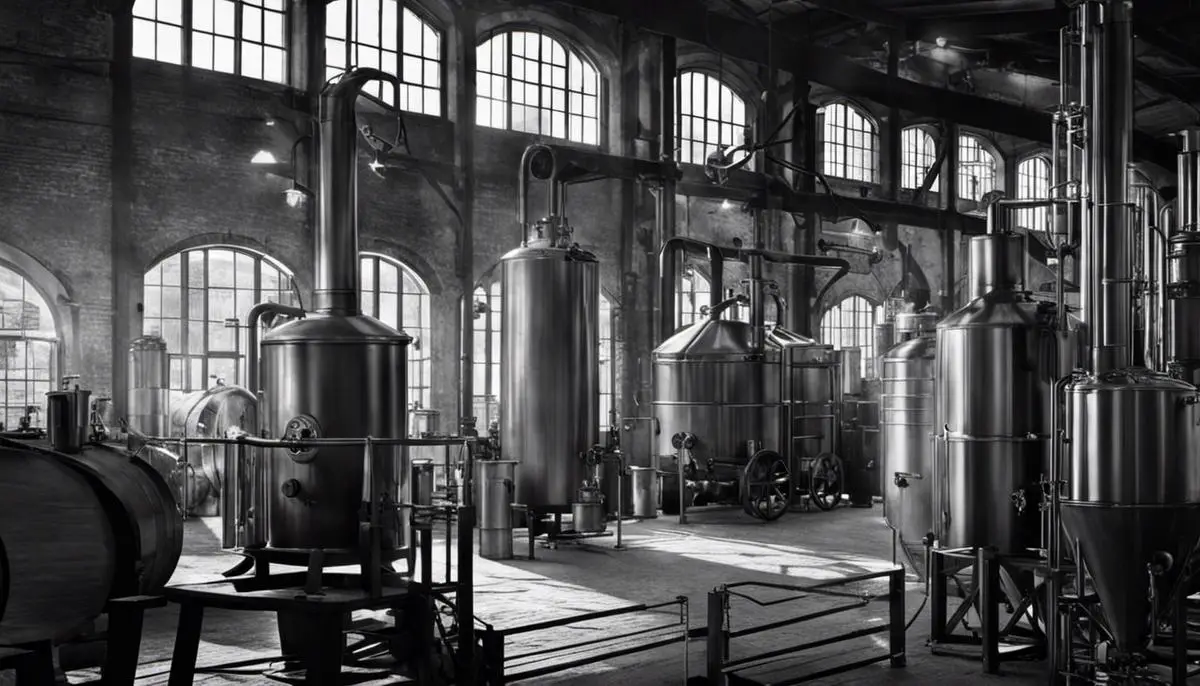

History and Importance of Gin Distillation

Origins of Gin Distillation

Gin distillation’s earliest roots date back to the Middle Ages, with the Dutch physician Franciscus Sylvius often credited as the inventor of gin in the mid 17th century. However, evidence suggests that the practice originated much earlier, possibly within Italy. The Italians were distilling wine and other fermented mashes, which would ultimately evolve into the distillation process for gin. The distillation of spirits in England flourished during the interim period of the 1688 Glorious Revolution, leading to the large-scale production and consumption of gin.

The Process of Gin Distillation

Gin distillation commences with fermentation, where grains such as barley, corn and wheat or molasses in some cases are transformed into alcohol via the action of yeast. Following fermentation, distillation occurs. The fermented wash is heated, causing the alcohol to evaporate due to its lower boiling point. This vapor then travels up a column and through a condenser, converting it back into a liquid. This process is usually repeated, improving the purity of the spirit.

Production Styles of Gin

There are several styles in which gin can be produced. The ‘Pot distilled gin’ represents the earliest style, incorporating a mix of fermented grain mash — from which the alcohol is drawn — that then steeps a range of botanicals to extract the flavors. ‘Column distilled gin’ commenced in the 19th century following the invention of the Coffey still. This method produces a high proof spirit that requires dilution and added flavor. In ‘Compound Gin’, the flavors are added to a neutral spirit without redistillation.

Gin’s Evolution over the Centuries

Throughout the centuries, gin distillation experienced significant evolution. In London during the 1700s, it was widely drunk due to its inexpensive nature, resulting in the ‘Gin Craze’ period. Post this phase, gin evolved into a more refined spirit, resulting in ‘London Dry Gin’. The 20th century ushered a revitalization of gin with several artisan and craft distilleries sprouting worldwide, creating innovative and diverse flavor profiles.

Cultural and Economic Importance

Gin distillation holds important cultural and economic significance. For instance, in London, the drink symbolically represents the city’s complicated working-class history. Economically, the gin industry contributes significantly to economies, particularly in the UK, where it supports thousands of jobs. Furthermore, the global growth in gin consumption in recent years has led to economic expansion in this sector, supporting local agriculture, providing employment and driving tourism.

The Harmony of Knowledge and Creativity in Gin Distillation

The process of gin distillation is a combination of science and art. Deep understanding of distillation mechanics and the ability to creatively curate botanical ingredients to create the bespoke flavor of gin is pivotal. Various factors including the specific ratio of botanicals to alcohol, the temperature and pressure at various stages of the process, and the maceration times can all influence the final taste, ensuring the uniqueness of each gin distillation experience.

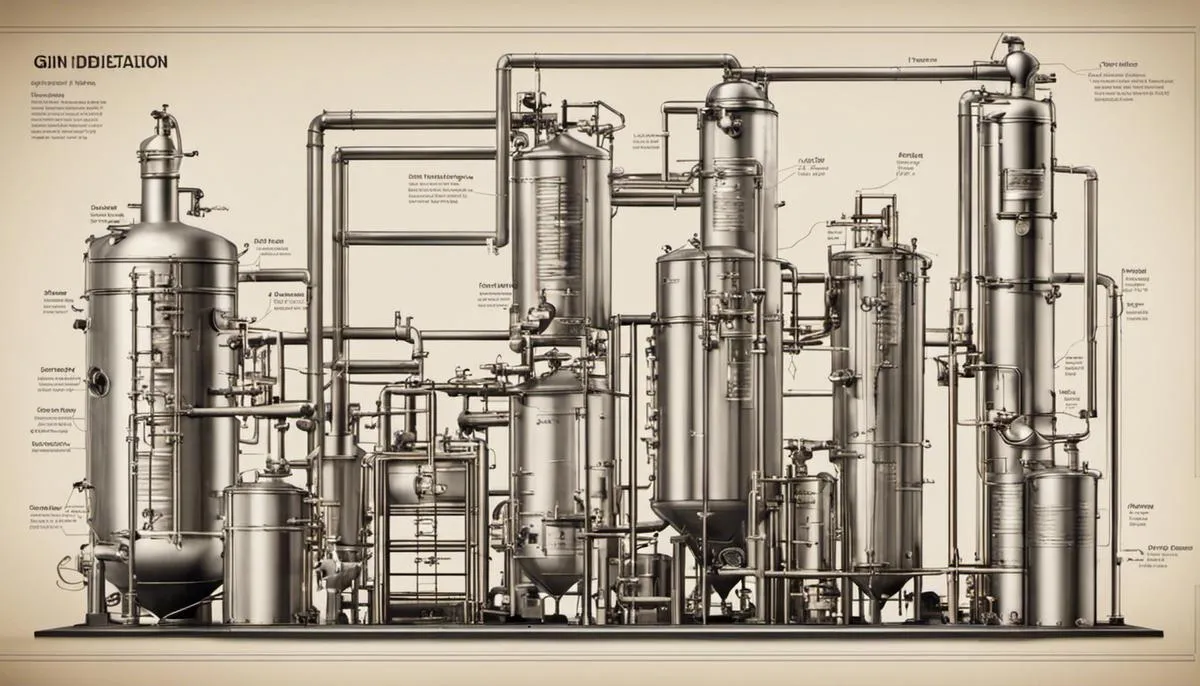

Gin Distillation Process

A Closer Look at the Basics of Gin Distillation

At its core, gin production is about the careful distillation of a fermented mix of grains, often barley, corn, or rye. This blend is submerged in heated water, provoking sugars to leach out, which are then transformed into alcohol during the fermentation stage when yeast is introduced.

Selection of Grains and Botanicals

Choice of grains can often influence the taste and character of the final liquor. While most gin producers use barley, it isn’t rare to find gin made from corn, wheat or rye. The grains are thoroughly cleaned before being milled to crack their hulls.

The signature feature of gin, however, is its distinct flavor derived from botanicals, with juniper berries as the most predominant among them. Producers often use a variety of other botanicals such as angelica root, coriander seeds, and citrus peels giving each gin its unique twist.

Fermentation Process

The fermentation process commences once the milled grains are combined with warm water to form the mash. This step aids in releasing the sugars within the grains which are then converted into alcohol by the yeast. This process can take several days, after which the result is a fermented liquid often termed “the wash” with an alcohol content akin to that of beer.

Distillation Overview

Post fermentation, the gin distillation process begins. This involves heating the fermented mash in a still. As the mash heats, the alcohol and flavors from the wash evaporate and travel up through the still’s column, passing through a condenser which cools the vapors turning them back into a liquid form.

Gin Botanical Infusion

In making gin, the aforementioned botanicals are introduced during the distillation process. Distillers have the option of either immersing the botanicals in the still along with the wash or placing them in a basket within the still’s column. Consequently, when the alcohol vapors rise within the still, they extract the flavors from the botanicals.

The Cut and Final Product

After distillation, a “cut” is made, which is a process of segregating the distilled alcohol into sections. The initial liquid, known as the “heads”, and the final liquid, termed the “tails”, are generally discarded due to their impure quality. The middle cut or “hearts”, however, is the highest quality spirit, and this is reserved for becoming gin.

Bottling

The final step in the gin distillation process is the watering down of the distilled spirit (owing to its exceedingly high alcohol content post-distillation) before it’s bottled. Producers often use purified water to bring the gin to the desired strength, which typically ranges between 37.5% to 47% alcohol by volume.

At its core, the manufacturing of gin is an art form, vitally dependent on judiciously selecting the primary constituents and meticulously overseeing every step of the process. It’s the minute nuances in this process that lead to countless variations of gin, thereby contributing to the diverse array of gins that we come across today.

Major Types of Gin and Their Differences

Understanding Gin Distillation

The distillation of gin, in general terms, includes the extraction of flavors from various botanical elements with juniper berries taking the center stage. This extraction is performed using a neutral grain spirit. The resulting concoction is then watered down using distilled water. The distinctive traits that categorize the wide variety of gins are fundamentally rooted in the unique distillation techniques employed and the diverse array of botanical blends utilized.

London Dry Gin

A classic gin variety is London Dry Gin, a style not geographically restricted despite its name. This gin is distilled in a two-step process, beginning with a neutral base spirit distilled to a very high proof. In the second distillation process, botanicals, predominantly juniper, are added to this spirit and the mixture is distilled once more. The resulting flavor is crisp and strongly juniper-forward, with no added flavors post-distillation. This creates a dry and simple gin, beloved for its versatility, clarity of flavor, and suitability for cocktails.

Old Tom Gin

Old Tom Gin, sometimes referred to as the “missing link,” bridges the gap between the London Dry and Dutch Genever styles. Its basic distillation process echoes that of London Dry, but it distinguishes itself in its unique point of sweetness. This sweetness comes either from adding sugar post-distillation or from arresting the distillation process prematurely, leaving residual sugars from the grain. This style was especially prevalent in the 18th century and provides a slightly sweeter, mellower alternative to the bracing sharpness of London Dry Gin.

Genever Gin

Coming from the Netherlands, Genever Gin, or Dutch Gin, is considered the progenitor of modern gin. Contrasted with the London Dry process, Genever employs a base spirit that’s more whiskey-like as it is made from malt grains, giving it a complex, malty flavor. The base spirit, known as ‘malt wine,’ is then re-distilled with botanicals, running the gamut from juniper to anise, ginger, cloves, and hops. The result is a fuller-bodied gin with a malty-sweet start and a botanical finish.

Contemporary Gin

As a contrast to traditional styles, Contemporary or New Age Gins experiment with distillation processes, botanical inclusions, and flavor profiles. Some distillers choose to use vapor infusion, where the botanicals are held in a basket through which the heated alcohol vapor passes, extracting the flavors more subtly. Other methods include cold compounding where botanicals are steeped in the spirit, or vacuum distillation that allows distillation at lower temperatures, preserving the delicate botanical flavors. The Contemporary Gin revolution has given birth to a multitude of gins with diverse flavor profiles, from citrus to floral and spicy.

Wrapping Up

Understanding the various gin distillation processes paves the way to fully appreciate the unique complexity of each gin style. From the boldness of a London Dry, the smoothness of an Old Tom, the richness of a Genever, to the novelty of a Contemporary variant, the method of distillation, along with the botanicals used, give each gin its distinctive character. This depth and diversity are what makes the gin a perfect spirit for a gin and tonic, a Martini, or a Negroni.

Sustainable Practices in Gin Distillation

The Shift Towards Sustainability in Gin Distillation

The alcoholic beverage industry is witnessing a positive change with distilleries placing a notable emphasis on sustainability. The focus is on lowering their environmental impact while ensuring the exquisite quality of their spirits remains uncompromised. Such sustainable changes range from using organic ingredients and employing energy-efficient distillation methods, to instituting effective waste management procedures in gin production.

Organic Ingredients in Gin Production

Organic ingredients are being increasingly used in gin distillation. An organic gin is manufactured using botanicals that have been grown without synthetic pesticides and chemical fertilizers. The use of these ingredients not only reduces chemical residue in the final product but also contributes less pollution to the environment during production. Some gin distilleries even grow their own herbs and botanicals, ensuring freshness and full traceability of ingredients.

Energy-Efficient Distillation Techniques

Energy efficiency is another fundamental aspect of sustainable gin distillation. Traditional distillation processes can be energy-intensive, especially during the heating phase. However, modern upgrades to distillation equipment, including the use of insulating materials and heat recovery systems, are mitigating these effects. Some distilleries utilize renewable energy sources such as solar or wind power for operation, drastically reducing their use of fossil fuels.

Waste Management in Gin Distillation

Waste management is a key focus in sustainable gin distillation practices. Gin production can yield several forms of waste, including spent botanicals and waste water. Rather than simply discarding these byproducts, eco-conscious distilleries are finding innovative ways to repurpose them. For instance, spent botanicals may be composted and returned to the soil, used in animal feed, or even repurposed as flavorings for food products. Meanwhile, waste water can often be filtered and reused in non-consumption processes within the distillery.

Sustainability and Product Quality

Embracing sustainable practices in gin distillation does more than just reduce environmental impact—it can also enhance the quality of the final product. Organic ingredients usually render a purer flavor, making the gin more appealing to consumers seeking high-quality, natural spirits. Plus, energy-efficient distillation and sustainable waste management often lead to cost savings in the long run, making sustainable gin distillation an economically as well as environmentally sound practice.

The Future of Gin Distillation

Gin distilleries worldwide are increasingly prioritizing sustainability, recognizing its benefits for both the business and the planet. As consumers become more environmentally conscious, demand for sustainably-produced gin is likely to grow. This trend is likely to continue, leading the way for emerging distilleries to adopt even more innovative and eco-friendly practices.

The exploration of gin distillation is not merely a technical endeavor, but it’s equally a journey illuminating the subtle artistry and innovation that shapes what we taste in our favorite gin cocktail. As we consider the diverse variants of gin and the unique distillation methods that create them, we appreciate the human innovation and creativity that challenges the norms and broadens the horizons of possibilities. The layers of the gin distillation world become further profound when we encompass sustainable practices showing how sustainability and quality come together to shape future paths. As the world becomes more eco-conscious, gin distilleries have become a testament to the industry’s agility and commitment to aligning with evolving consumer values, stewarding a lasting legacy for future generations.