If you’ve ever had a sip of a classic gin and tonic, or perhaps a dry martini, then you’ve experienced the allure of gin. The crisp, fragrant spirit has carved a niche for itself in the world of spirits. Yet, how many of us really know where gin originated, or the process involved in its production? Delve into the fascinating world of gin production with our comprehensive guide. Unearth the captivating history of gin, explore the different types and distilling methods, discover the botanical ingredients influencing its distinct flavor, navigate through the complex regulations and labeling practices, and finally, unravel the intricacies of the gin production process. Let’s embark on this illuminating journey.

History of Gin Production

The Beginnings of Gin Production

Gin traces its origin to the Middle Ages, being originally developed for medicinal purposes. The 17th century in Holland marked a significant time in gin’s history, as it gained acceptance as a drink. Dutch doctor Franciscus Sylvius is contributor towards the creation of gin, advocating its diuretic qualities, and dubbing it “genever,” deriving from the Dutch word for juniper.

The Evolution of Gin Production and Distillation

During the early phases of distillation, gin was produced by a simple distillation process. Low-cost grains were commonly soaked in water until sprouting occurred, releasing sugars for fermentation into alcohol. The distillation of this mixture followed, with the addition of juniper berries and other botanicals to mask the harsh flavor.

By the 1700s, England was producing large volumes of low-quality gin. The Gin Act of 1751 only allowed licensed professionals to distill gin, which helped eliminate unscrupulous producers and enhanced the quality of gin.

The 19th century brought significant advancements in distillation techniques, enhancing the gin production process. The introduction of the continuous column still yielded superior control over distillation, producing a purer and smoother spirit known today as London Dry Gin.

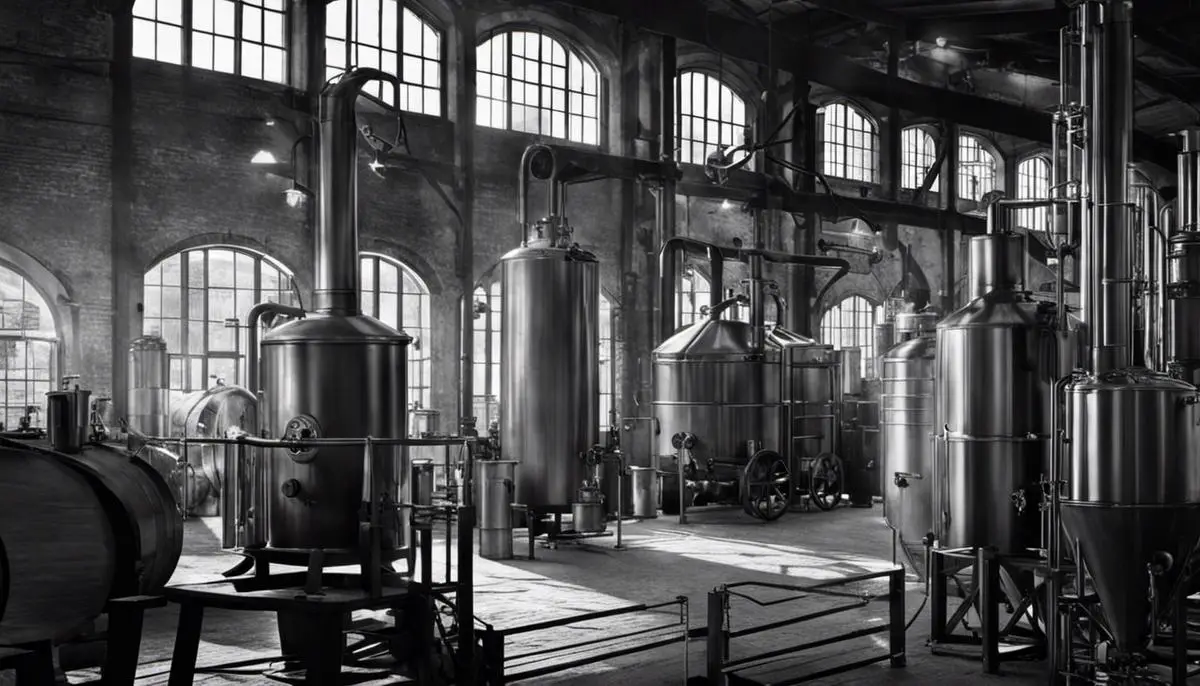

In current gin production, the quality of ingredients has improved, rules have been tightened, and production methods have become more sophisticated. The gin industry has seen a revival, with a surge in boutique distilleries. These artisan gins often emphasize unique flavors achieved by utilizing a variety of botanicals.

Present-day Gin Production

Today, gin production is predominantly divided into two types: pot and column distillation. The pot method immerses botanicals in a neutral spirit before redistilling, producing a strong flavor profile. Conversely, column distillation allows superior control, yielding cleaner and more delicate gins.

The current gin market is noted for its variety, boasting a plethora of gin types with unique production methods and flavor profiles. Artisan gins have gained popularity, many using locally sourced botanicals to offer a singular experience for consumers, while established brands reliably offer their consistent products.

Certain regions around the world have their signature gin, ranging from the London Dry and Plymouth gin in the UK, to the Old Tom in the US, and even the Beefeater style enjoyed by many worldwide.

While the techniques and flavors of gin have progressed over the years, the central ingredient, the juniper berry, remains true to tradition, providing gin its distinctive and traditional taste.

Types of Gin and Distilling Methods

London Dry Gin

The gin variety recognized and loved worldwide is the London Dry. Despite its origins in London, its production isn’t tied to a specific geographical region. The term ‘London Dry’ pertains to the distinct method of producing the gin. London Dry Gin is characterized by the requirement that all flavorings, predominantly juniper berries, must be natural and integrated during distillation. No flavors or colors can be introduced after distillation. The final product is a clear gin that is typically fresh and dry, delivering a clean, botanical taste.

Plymouth Gin

Similar to London Dry Gin is the Plymouth Gin, with a geographical indication restricted to the city of Plymouth, England. The flavor profile of Plymouth Gin is somewhat softer, less dry than London Dry, with an earthier finish, but still keeping the botanical character. Juniper berries still remain the predominant botanic, yet it is less harshly evident.

Old Tom Gin

Old Tom Gin represents a slightly sweeter style of gin. Originated in England, it played a significant role during the Gin Craze of the 18th Century. Its taste rests somewhere between London Dry and the sweeter Dutch Jenever, causing its emergence as a transitionary gin drinking preference. Old Tom Gin commonly incorporates licorice root in the distillation process, yielding this sweeter profile.

Naval Strength Gin

A high-proof gin, typically around 57% alcohol by volume is referred to as Naval Strength Gin. This term is linked to the British Royal Navy which reckoned that gunpowder soaked in high-proof gin would still ignite, hence assuring the proof of spirits onboard. Like London Dry, Naval Strength Gin offers a botanical-driven flavor, yet the high alcohol content provides a potent punch.

Compound Gin

Compound Gin is a style where flavorings are adhered post-distillation by simple infusion. This method is commonly employed by home gin makers or small-scale distilleries. However, it’s worth noting that this style isn’t recognized as a category of gin in European legislation due to its distinct method leaving a less refined, more rustic flavor.

Into the Distillery: Distillation Methods

Gin production primarily employs two distillation techniques – pot distillation and column distillation. The pot distillation method mixes neutral grain alcohol with water and chosen botanicals, heat infusing the mix together. The vapors collected post heated distillation capture the flavors of the botanicals. This entire process takes place in a single batch hence it’s also known as the batch method.

Column distillation, on the other hand, allows for continuous distillation. The alcohol is constantly cycled through the system, generating a higher proof spirit. This method provides a more neutral and cleaner tasting spirit often the base for premium and super-premium gins.

Choosing the Botanicals

Gin’s distinguishable character comes from the botanicals used during the distillation process. The law requires that juniper must be the predominant flavor in gin, yet a multitude of other herbs, roots, spices, and fruits comprise gin’s flavor. Some common botanicals besides juniper include angelica root, citrus peels, coriander, and orris root. Distilleries frequently have their own secret recipes and methods of infusing these botanicals to keep their gin unique and distinct.

When considering gin, the specific type, along with the method of distillation, play substantial roles in determining its final aroma and taste profile. Each variety and technique presents its own unique palette experience, creating a myriad of possibilities for gin lovers. Achieving the perfect blend of both elements and processes forms the backbone of producing a high-quality gin.

Ingredients used in Gin Production

Crucial Components in the Production of Gin

As one ventures deeper into the world of gin production, the process is seen to primarily revolve around three essential elements: grain, water, and juniper berries. The foundation for the majority of gin spirits is obtained from grains such as wheat, barley, or rye. This grain selection is converted into a fermented mash that is later distilled into a high-alcohol spirit.

The subsequent step incorporates water to reduce the spirit to an agreeable strength for consumption. The quantity of water used fluctuates, and this variation influences the taste as well as the quality of the final brew. Frequently, distilled water is employed to preserve a neutral flavor and ensure the clarity of the gin.

The vital and distinguishing component of gin is the juniper berry. Legal guidelines mandate that the predominant flavor of gin should be juniper, lending the spirit its signature pine-like, earthy aroma and taste. Typically, these berries are dried and ground before they are introduced into the mix. The distillation process then enables the potent oils of the crushed berries to release, subsequently creating that distinctive gin flavor we all recognize and love.

Role of Juniper Berries in Gin Production

Juniper berries play a pivotal role in bringing the unique taste and aroma to gin, giving the spirit its essence. During the distillation process, the berries – often combined with other botanicals – are heated, and the epithelial lining inside the berries boils and turns to vapor. This vapor is then condensed back into liquid form, marrying the depth and complexity of juniper with the base spirit. The process results in gin’s distinctive, invigorating flavor profile.

Botanicals in Gin

Besides juniper, a myriad of other botanicals is used to further enhance the flavor and aroma of gin. These botanicals can be roots, barks, seeds, spices, fruits, and even peels. Each gin producer keeps their list of botanicals a closely guarded secret, but some common ones include coriander seeds, angelica root, orris root, lemon peels, and orange peels.

Coriander seeds contribute to gin’s spicy, nutty flavor, while angelica root lends a musky and earthy undertone. Orris root functions as a fixative, helping to enhance and preserve the bouquet of the aromas and flavors during distillation. Citrus peels, including those of lemons and oranges, are often used to impart bright, zesty character to gin.

Infusing Gin with Distinct Flavors

While juniper is the dominant flavor, the additional botanicals used serve to create a unique taste, giving each gin brand its signature character. The proportions and types of botanicals used will greatly influence the flavor profile of the gin, making some brands more floral, others more citrusy or spicy.

Apart from the ‘pot distillation’ method mentioned earlier, there is also the ‘vapor infusion’ method. Here, botanicals are put in a basket in the still, and as the vapor ascends through the basket, it picks up the flavors of the botanicals, resulting in a more subtle, refined gin.

Gin producers may also choose to perform a post-distillation infusion, where botanicals are steeped in the distilled spirit before it is re-distilled. This brings a distinct depth of flavor and complexity to the spirit, which is then filtered and diluted before being bottled.

At the heart of every bottle of gin, regardless of the various botanical blends and flavour profiles originated, a discerning palate will always detect the omnipresent essence of juniper berries. This complex element imbues an intoxicating aroma of pinewood and exhibits a captivating taste that lures gin enthusiasts across the globe.

Gin Regulations and Labeling

Regulations and Labeling Practices in Gin Production

Grasping the complexity of gin production involves not just an understanding of the distillation process, but it also necessitates familiarity with legal requirements imposed by international regulatory bodies. Such regulations significantly influence how gin is conceived and eventually marketed.

In the United States, the Alcohol and Tobacco Tax and Trade Bureau (TTB) takes the helm in governing gin production. Amongst various stipulations, the salient rule states that juniper should be the defining flavor of gin; reinforcing the characteristic taste we associate with gin.

Conversely, the European Union delves deeper with their regulations, stratifying gin into four particular categories: gin, distilled gin, London gin, and sloe gin. Each type subscribes to a unique regulation. For example, for a gin to bear the ‘London’ designation, all its flavors must manifest from natural sources, with the alcohol and flavors jointly distilled. Notably, the usage of synthetic flavors or colorings is strictly proscribed.

A common regulatory criterion amongst all governing bodies is the compulsory minimum alcoholic volume in gin. This is fixed at 37.5 percent by the TTB and 40 percent by the EU, as a measure to maintain specific quality and safety standards in all gin production and sales.

Understanding Gin Labels

When holding a bottle of gin, it is interesting to note that the colorful artwork and complex phrases hold specific meanings, enforced by the same governing bodies that regulate gin production. Typically, a gin label will display the type of gin, the alcohol content by volume, the distillery where it was produced, and the country of origin.

Some labels may also contain a phrase stating the gin is “distilled” or “London dry.” These terms indicate the specific production process the gin underwent. A bottle labeled with “distilled gin” signifies that it went through a second distillation process with botanicals, while “London dry” refers to a method in which all flavorings are natural and added during the distillation process, not after.

Other information that can often be found on a gin label includes the list of botanicals used during distillation. This is usually unique to each individual brand and can range from a handful of different botanicals to dozens.

The regulations and rules that govern gin production and labeling not only preserve the quality and safety of gin but also relay information from the distiller to the consumer, allowing for an informed buying decision.

To fully appreciate the intricacies and subtleties that define each bottle of gin, it’s crucial to gain insight into the intricate network of distillation processes, regulations, and labeling codes. These behind-the-scenes elements significantly influence the final product’s quality and flavor.

The Gin Production Process

Gathering the Raw Ingredients

The production of gin heavily revolves around one agricultural component – the juniper berry. However, a variety of other plant extracts and spices, known as botanicals, also play a critical role in enhancing the flavor and complexity of the spirit. Juniper berries, plucked from the juniper bush, experience diverse climatic and geographical influences as these bushes are globally distributed. Additional botanicals can range from coriander seeds, angelica root, and orris root to citrus peels, cardamom, and cassia bark. The exact recipe and proportion of these botanicals vary from one producer to another, resulting in a unique and distinct gin variety.

Intensive Preparation Process

The gin production process begins with creating a neutral spirit, a base alcohol usually distilled from grains like barley, corn, or wheat. The spirit must be of high proof, typically over 90% alcohol by volume (ABV), and should carry no flavor. The neutral spirit is then diluted with water to lower the alcohol percentage before beginning the flavoring process.

Flavoring the Spirit

In the flavoring process, known as steeping, the botanicals are added to the diluted neutral spirit and left to infuse for a period depending on the manufacturer’s recipe and the desired flavor profile. During this process, the alcohol extracts the flavors and essential oils from the botanicals.

Distillation

Once the botanicals have steeped for the desired time, the spirit is then re-distilled. During distillation, the alcohol vapor passes through a condenser and liquefies. Particular attention is paid to the “cut points,” or the beginning and end of the distillation, as these contain compounds that can affect the taste and quality of the final product.

Post-distillation Process

After distillation, the gin can be left to rest for a few weeks to allow the flavors to integrate. Sometimes, additional flavorings, such as fruit extracts, may be added post-distillation.

Dilution

Then, the alcohol strength of the gin is reduced by adding water. This stage is crucial to ensure the gin is at the right proof for bottling. The vast majority of gin is bottled at between 37.5% and 47% ABV, though this can vary.

Final Filtration and Bottling

The distilled gin now undergoes a final filtration to remove any remaining impurities. After the filtration is completed, all that remains is the bottling, which usually takes place on a high-speed bottling line. Some smaller producers may still bottle by hand. The product is now ready to be distributed and enjoyed worldwide.

Aged Gin

While the majority of gin is unaged and clear, there is a category of aged gin which is gaining popularity. This type of gin is placed in oak barrels for a varying period of time, taking on color and flavors from the wood of the barrel in a similar way to whisky or rum.

Craft Gin Production

As the gin market grows, so do the methods of production. Craft distillers are continuously experimenting with different botanicals and production processes, leading to an increasingly diverse range of flavors. Quintessentially, the precise blend of botanicals, timing, and techniques used are what make each gin uniquely their own.

Sustainability in Gin Production

Sustainability is a growing priority for gin manufacturers, with many thinking about how they can produce gin in an environmentally-friendly manner. Some distilleries are growing their own botanicals, using locally-sourced ingredients, and employing renewable energy sources in their production facilities. This approach not only reduces the environmental impact of gin production but often results in a superior-tasting product as well.

Immersing ourselves in the world of gin, we have traveled from its intriguing history, inspected various types and their distilling methods, and highlighted the key role of juniper berries and other botanicals in shaping its flavor. The complexity of gin regulation, labeling, and the finesse required in the gin production process subsequently came under review as well. All this culminates in a richer understanding of the spirit that arrives in our glass. The next time you appreciate a gin-infused cocktail or a simple gin and tonic, remember the efforts, tradition, and ingenuity that have brewed the delightful gin in your hand.